Here at The Magneto Guys, we get a lot of enquiries about V twin magnetos, the majority of which relate to those fitted to Vincent V twins. Hopefully, most of the questions asked will be covered by the information given in the following summary.

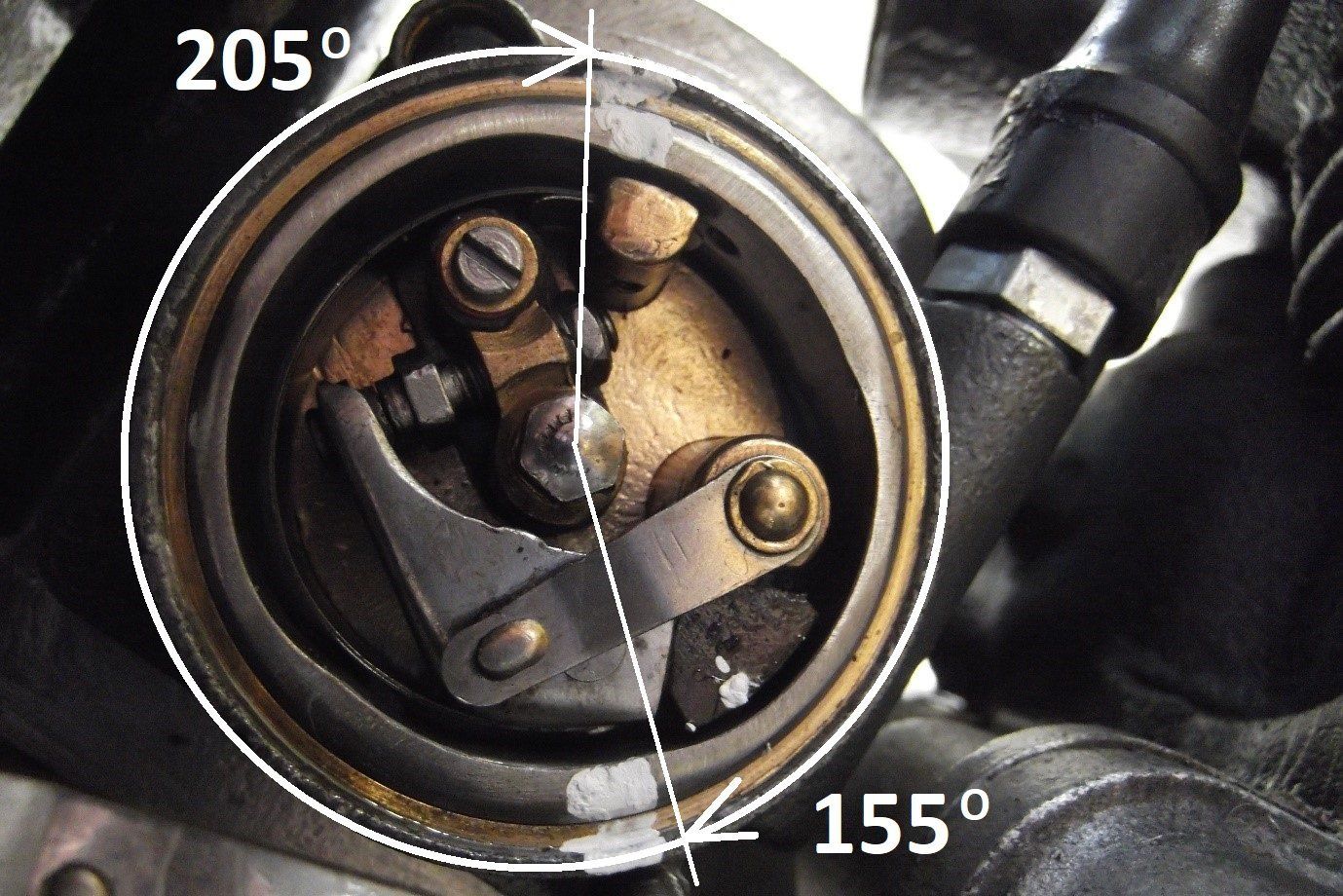

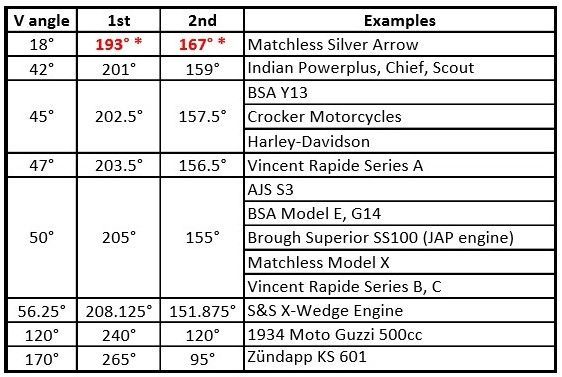

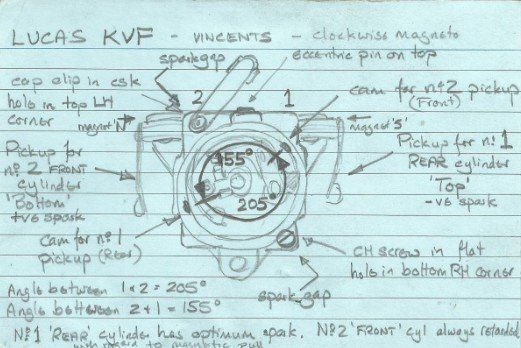

Apart from the cam ring, the internals of a Vincent’s Lucas KVF magneto are more or less identical to the K2F magneto as fitted to BSA and Triumph twins. These magnetos all follow the pattern of a conventional rotating armature design and so have two break points 180° apart. However, only one of the bumps on the Vincent cam ring can be made to coincide with a break point. As a result, only one cylinder receives a good spark whereas the other cylinder receives a much weaker spark because the points open long after the break point by which time the magnetic field has been collapsing for an appreciable time. A situation which is far from ideal and is, perhaps, one reason why starting engines fitted with Lucas KVF magnetos is not always easy.......

As explained on the Spark Polarity

page, twin cylinder magnetos deliver a positive voltage to one spark plug, and a negative voltage to the other. Vincent magnetos are magnetically polarized so that the front cylinder receives the negative voltage as this is the one that receives a lesser quality spark from the ‘retarded’ side of the magneto.

No 1 - rear cylinder

Higher HT lead when fitted to engine - adjacent to magnet’s N pole

Cam position gives optimum magneto timing (strongest spark)

Positive (weakest) spark

Rotates 205 degrees then.......

No 2 - front cylinder

Lower HT lead when fitted to engine - adjacent to magnet’s S pole

Cam position gives retarded magneto timing (weakest spark)

Negative (strongest) spark

Rotates 155 degrees then......

No 1 again

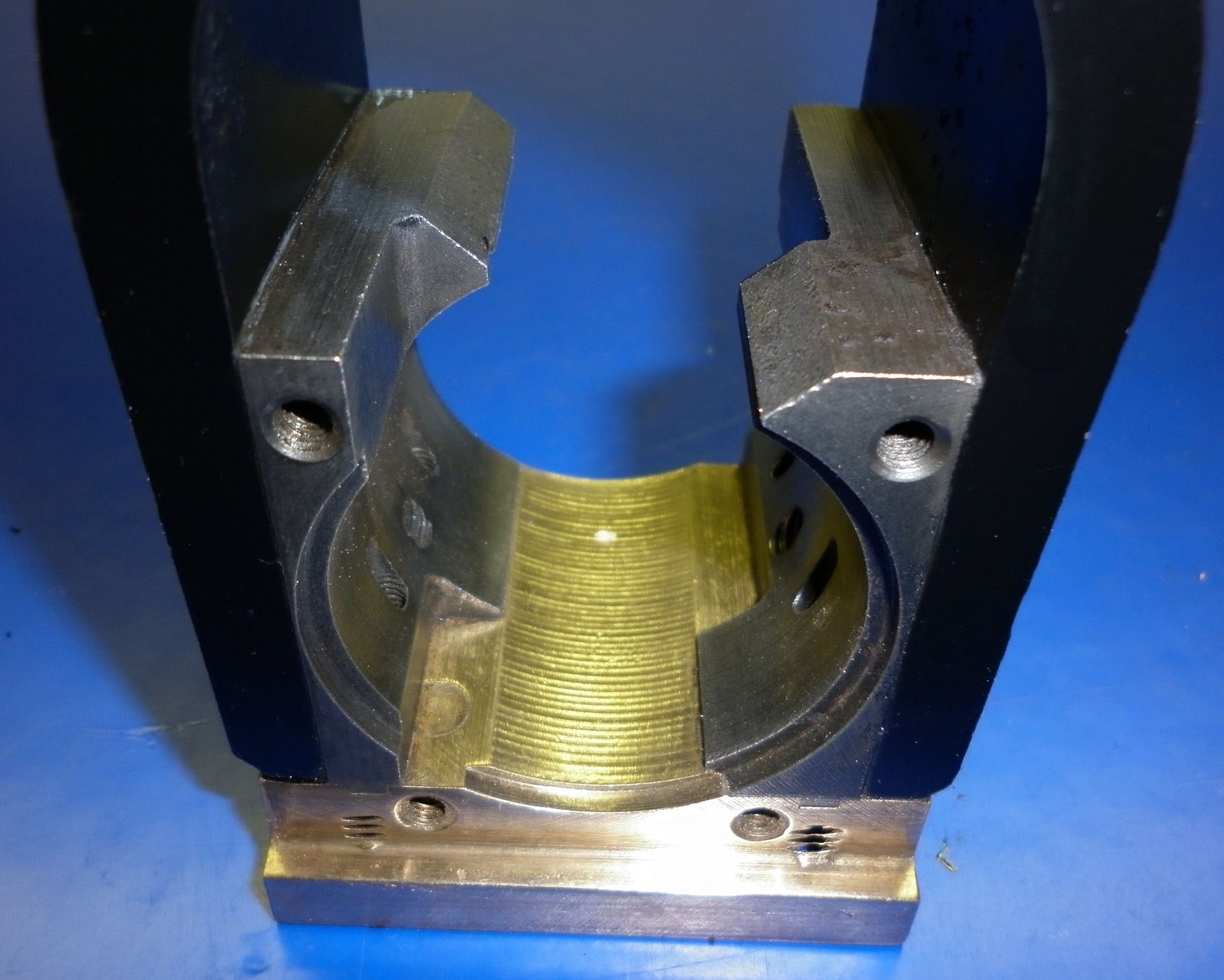

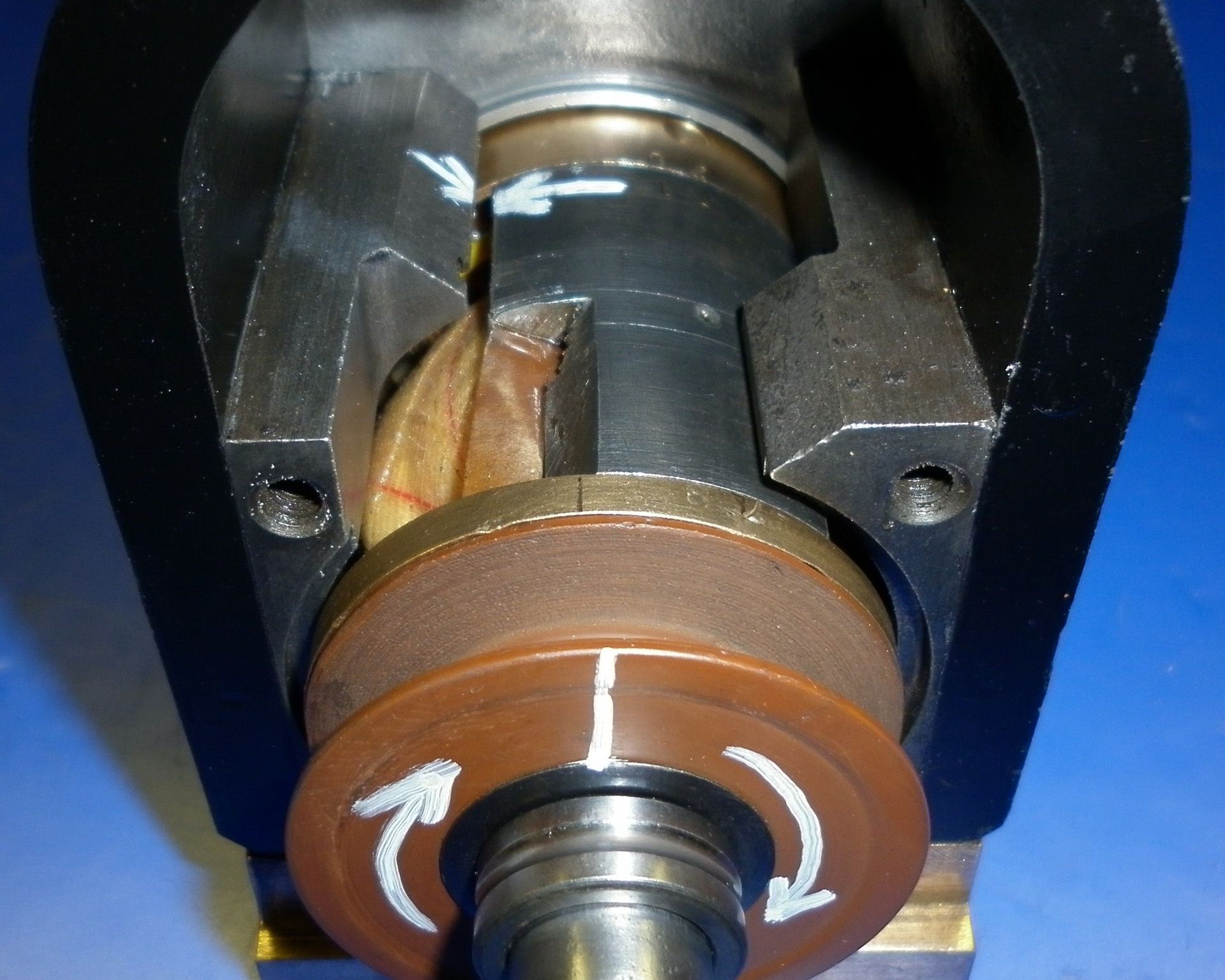

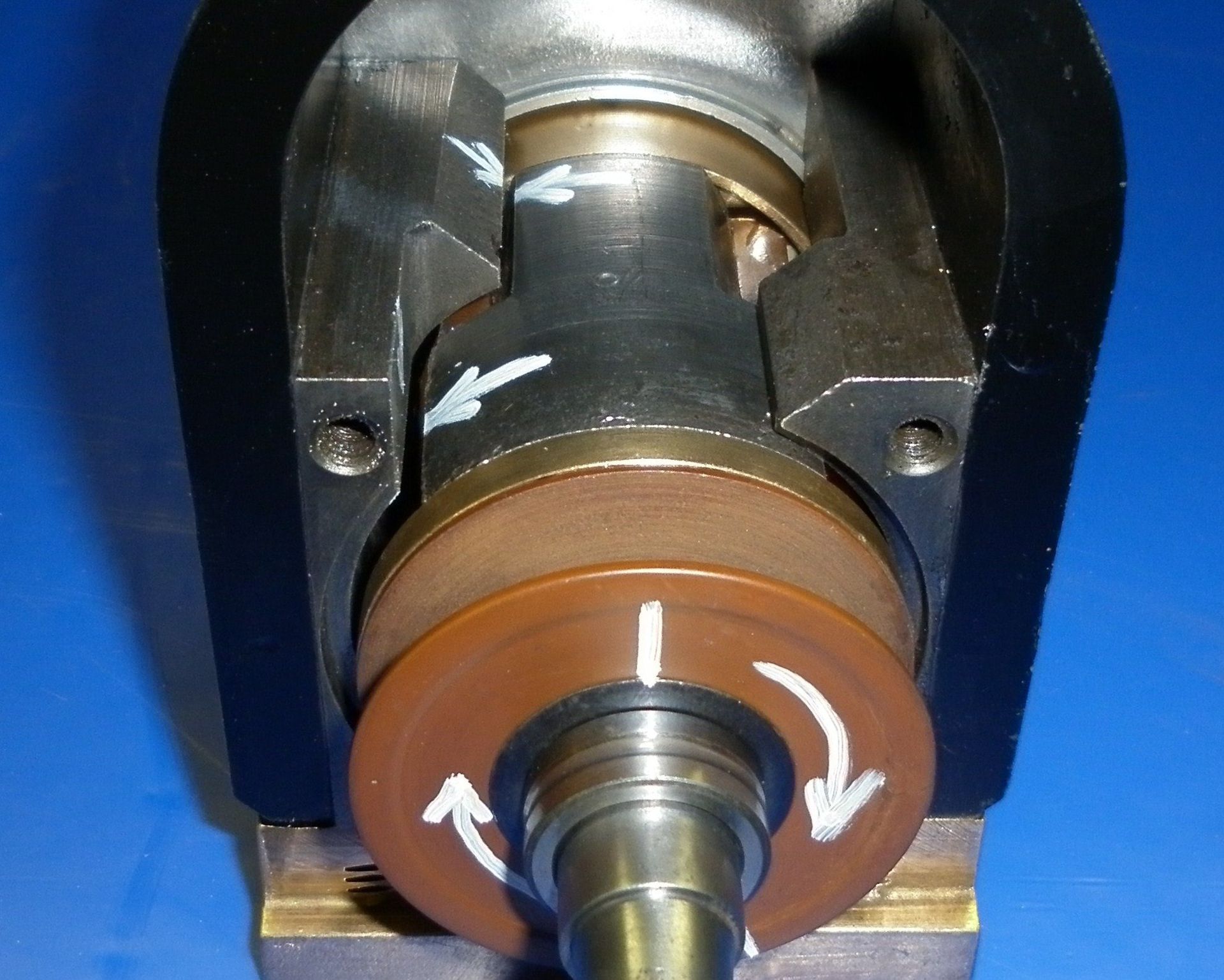

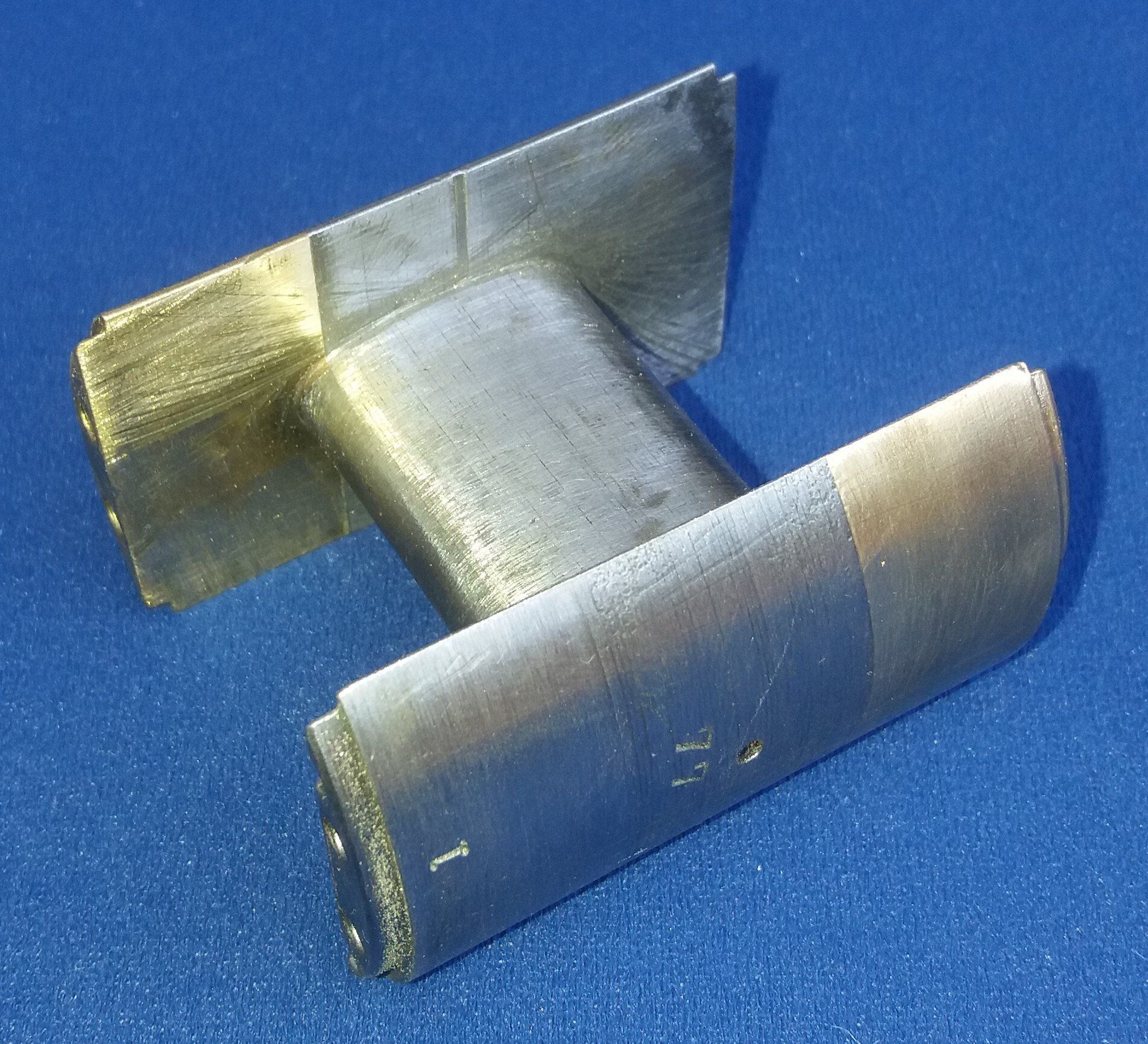

The Vincent KVF magnetos are clockwise rotation whereas most K2Fs fitted to British twin motorcycles are anticlockwise magnetos. One exception is the Royal Enfield twins which use clockwise magnetos. The cam ring used on a KVF magneto is obviously different to the one used on parallel twin K2F magnetos but there are other differences too. Vincent KVF magnetos have the cam ring housing fitted so that the eccentric pin used for cam ring location is at the top, The clip for the points cap goes in the countersunk hole in the top LH corner next to the ‘2’ stamping. The cheese head screw goes in the flat hole in the bottom RH corner. Note that KVF bodies (and clockwise K2F bodies) have spark safety gap screws in line with the cap clip and cheese head screw.