Rewinding Magneto Coils - Materials

Rewinding Magneto Coils - Materials

This page describes all the materials The Magneto Guys use when rewinding magneto coils . We hasten to point out that we do not supply these materials. Yes, this is what we use to repair magnetos so we have stocks here but they are for our own use. We do not have the time or the facilities to become mail order parts or materials suppliers. As always, we are happy to make suggestions of where these items are available - just contact us

and let us know what you are looking for!

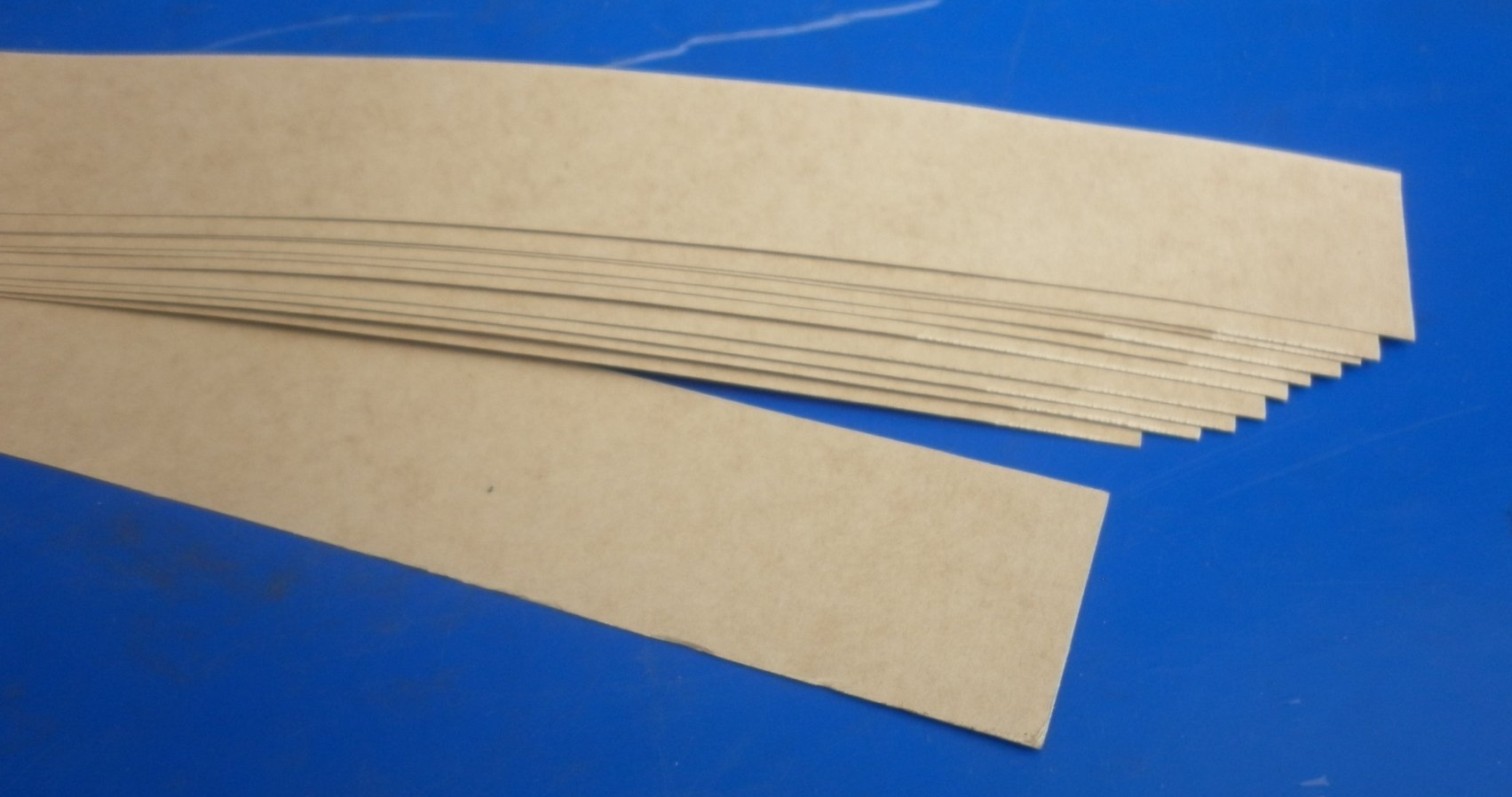

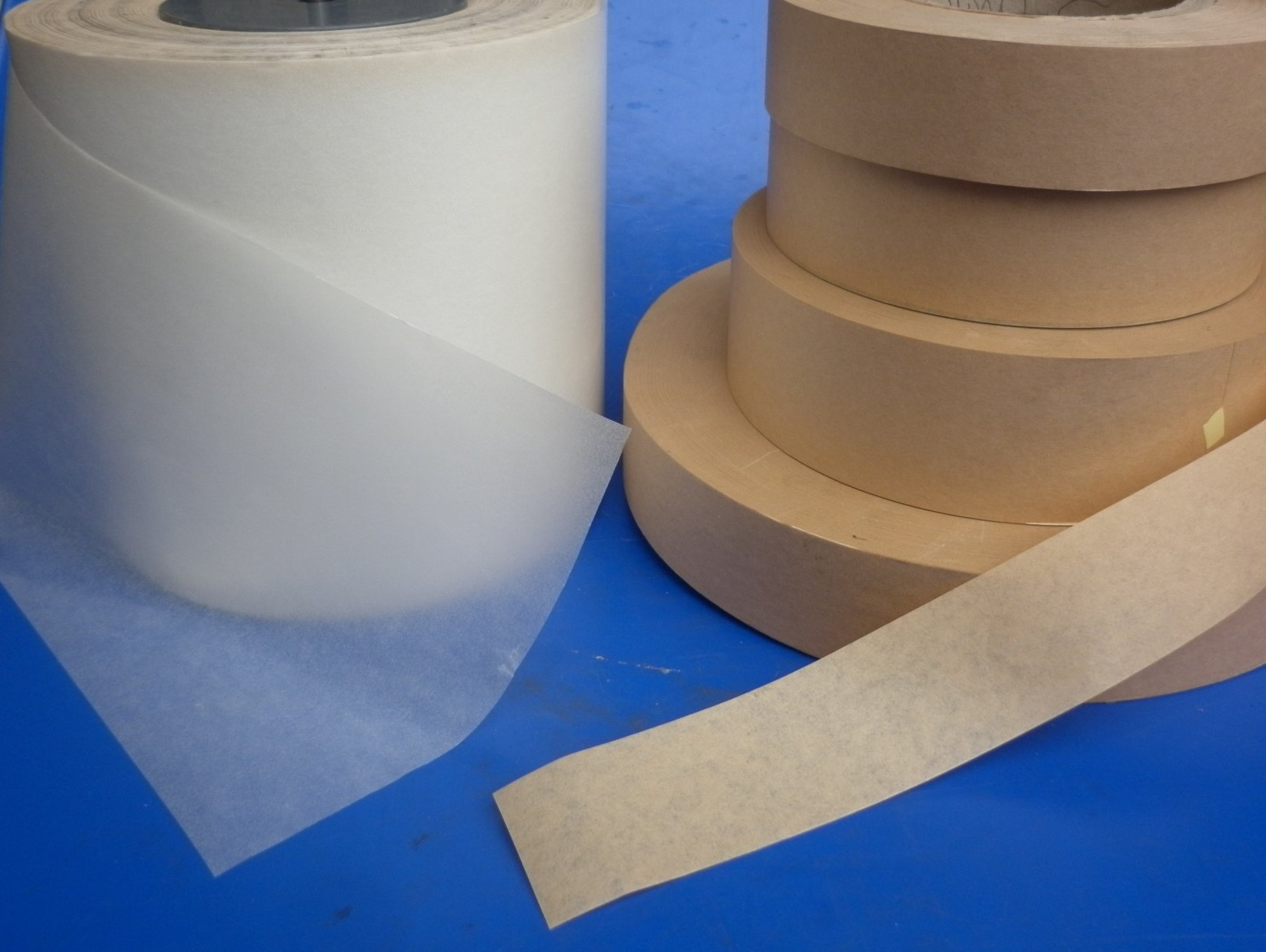

Secondary winding interleaving insulation:

Usually kraft paper, 0.002” thick. We buy this in rolls of different widths from 34mm to 50mm to suit different magnetos. Sometimes we use 0.001” thick Glassine on small coils. This is on a 6" wide roll which we cut to the required width using a paper guillotine.

Silvered Copper Foil: This was originally made for use in the stained glass trade. We came across this tape a few years ago and tried it out. The silvered surface is very easy to solder to and the fact that it is self adhesive makes it very versatile. We use it at the end of the secondary winding where it is joined to the HT connection. Available in a range of widths, we use the 1/2" wide version.

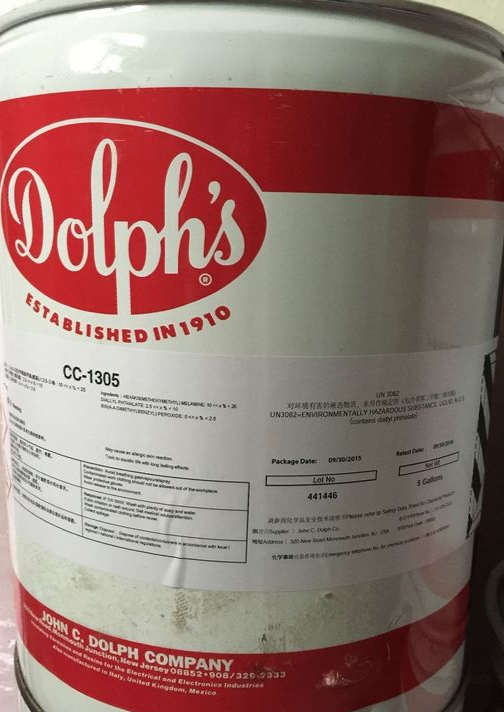

Varnish:

Dolphon CC1305 High flash, solventless polyester resin with high thermal conductivity. Cured by baking at 120°C for four hours. Once cured, provides excellent electrical insulation properties. It also provides mechanical support to the winding so that it is not affected by vibration or the centrifugal forces experienced by rotating coil magnetos.

The Magneto Guys

Telephone: +44 (0)1323 840203