Magneto Internal Timing

Explaining the internal timing of a magneto may be easier with the help of the following pictures.

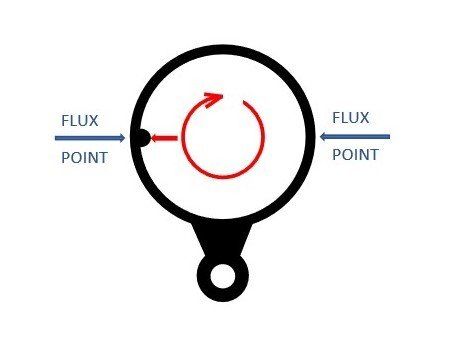

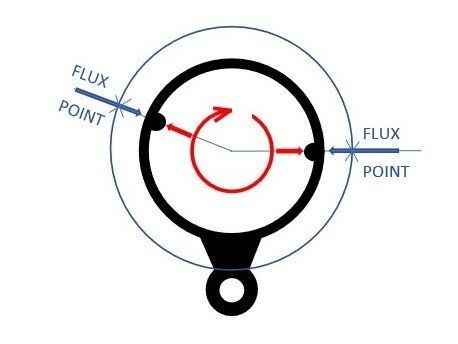

This first picture shows the points, indicated by the red arrow, rotating in a clockwise direction. As the points pass the bump on the black cam ring, they open and the magneto produces a spark. Note the bump on the cam ring opens the points at the magneto flux point. (In practice the best position is just after the flux point as that is when the magnetic field is collapsing but is shown in line here to simplify the description.) Note that there is only one bump on the cam ring so this is the set up for a single cylinder magneto. The second flux point, at 3 o'clock in the picture, is not utilised in single cylinder magnetos.

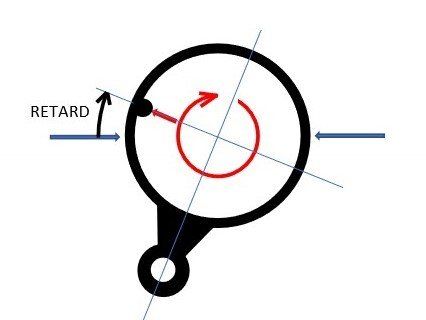

When the cam ring is rotated in the same direction as the rotation of the points, the points reach the cam a little later than before. The points open a number of degrees after the best position and this means that the spark is slightly weaker. The more retard, the weaker the spark. This movement of the cam ring results in the ignition timing of the engine being retarded.

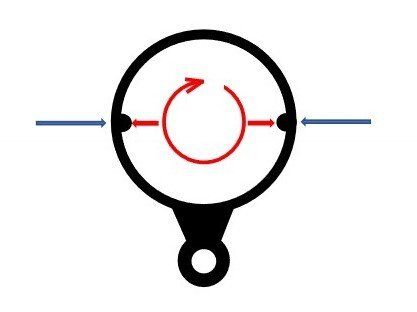

Here, one of the cam bumps has been moved so that the angle between the two bumps is unequal. This arrangement is used for a V twin magneto. What the actual angles are between the bumps depend on the angle between the cylinders as explained on the V Twin Magnetos page. Note that the two flux points remain at 180° apart on this picture. This means that one cylinder will be given the best spark and the other will be retarded because the points open late on that side. This would work OK - the Lucas KVF magnetos fitted to Vincent V twin motorcycles used this arrangement.

Unfortunately, having a late spark with the cam in the fully advanced position means that it becomes even later if the cam lever is moved to retard the ignition timing. This may mean that the internal timing of the magneto on that side is so late that the magneto is unable to produce a spark at all. That's why Vincents are not fitted with a manual advance and retard facility, relying instead on an automatic mechanism to provide ignition advance and retard. For a V twin magneto to work at it's best, one of the flux points needs to be moved so that they both line up with the bumps on the cam again. How this can be achieved is explained on the V Twin Magnetos page.

Here at The Magneto Guys, we are often asked if a 180° twin magneto can be made into a V twin magneto or if, for instance, a 50° V twin magneto can be made into, say, a 45° V twin magneto, simply by changing the cam ring to one with the appropriate angles between the two bumps. The simple answer is yes, provided that the one best spark, one retarded spark situation explained above is considered acceptable. If doing a conversion in this way, it is vital that due care is taken with fitting the new cam ring to ensure that when one bump is on time, the other is late.

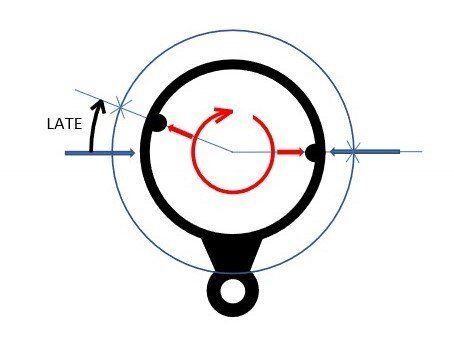

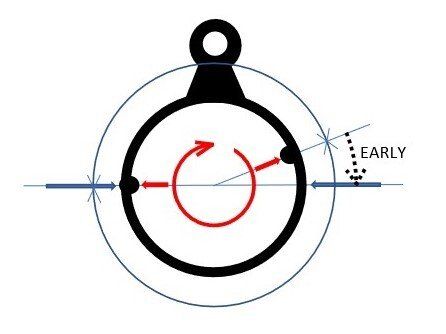

In this picture, the cam ring is turned around compared to the previous pictures. Yes, one bump on the cam ring lines up nicely with one flux point but notice that the other bump will now open the points too early. The first bump will work OK but the other bump will NOT produce a spark. This is because the internal timing of the magneto is such that the points on that side will be opening too early - before the magnetic field starts to collapse.

All the above information refers to the cam ring, points and flux points. In addition to this, if converting a 180° magneto V twin magneto to work as a V twin magneto, it will also be necessary to check that the brass segment on the slip ring lines up with both pickup brushes. If they don't line up, the slip ring will need to be changed.

In much of the explanation above, use of the terms 'best spark', 'retarded', 'early' and 'late' and so on is mostly referring to the internal timing of the magneto. This is NOT the same as the ignition timing of the engine.

Internal timing of the magneto is set by the way the magneto itself is assembled. When set correctly, it ensures that the points open when the armature is in the position where the magnetic field has just started to collapse. This ensures that the magneto is able to give the best possible spark.

Ignition timing of the engine is determined by the linkage between the magneto and the engine to ensure that the spark generated by the magneto occurs when the piston is in the correct place in the cylinder towards the top of the compression stroke.

Use of a manual advance and retard lever - usually fitted on the magneto - will allow the ignition timing of the engine to be changed to suit the load conditions. Unfortunately, on most magnetos, it will also alter the internal timing of the magneto. The design of some magnetos is such that this does not happen and they produce the best possible sparks irrespective of where the advance and retard lever is positioned.

It is important to understand the internal timing of a magneto if parts are to be interchanged between magnetos. Here are just some of the pitfalls which can catch out the unwary!