Fitting HT Leads

Fitting HT Leads

High Tension (HT) leads consist of a single conductor covered in an insulation layer several times thicker than the conductor. This thick insulation layer - PVC, EDPM or silicone or a combination of them - is necessary to prevent arcing through the insulator to an earthed part of the engine.

Early HT leads used a copper conductor, sometimes tinned, made up of a number of separate strands. They work very well but do create radio interference which may be a problem. More modern types of HT leads use a conductor made of compressed carbon powder or stainless steel wire wound as a coil. Both of these later types of conductors have an inherent resistance and may be used in conjunction with plug caps and/or spark plugs each fitted with an internal resistor. This combined resistance acts to suppress any radio interference. Unfortunately it also reduces the voltage at the spark plug which means that, to achieve a spark at the plug, the magneto needs to generate a higher voltage in the first place. For this reason, magnetos should always use copper cored HT leads, unsuppressed plug caps and resistor-free spark plugs so that the magneto is not over stressed!

HT cable is available in a variety of colours, including cloth covered and also in several different diameters. The majority of standard HT cable used for vehicles is 7mm in diameter. A smaller, 5mm cable is often used for mopeds, some small motorcycles and garden machinery. Many veteran cars used a larger 9mm cable.

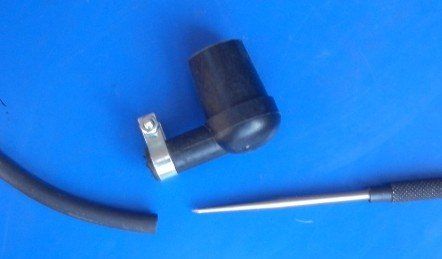

Sometimes the HT lead is connected to the distributor cap using a stud and threaded knob. One way of making a good connection is to use a curtain wire eye. It is a good idea to use a sharp point such as a scriber to start a hole in the end of the HT lead, The eye is then easily screwed into the copper core of the cable.

The same technique can be used to fit plug caps which use a screw type connection. It is all too easy to screw the cap on the end of the cable and to miss the copper conductor altogether.....

Some distributor caps use a pointed screw to pierce the insulation of the HT cable and make contact with the copper core conductor. Don't be tempted to just wind the screw in expecting the pointed end to force it's way through the insulation. The insulation can be quite hard - particularly at low temperatures. On some distributor caps and pickups, especially reproduction ones, the thread is only tapped into the insulation material that the unit is made of rather than into the brass terminal so is quite weak and easily stripped.

Our recommendation is to push the HT lead all the way home into the cap and then use a small drill to place a pilot hole through the cable insulation. An alternative is to cut a small V through the insulation with a sharp knife.

The same technique is used on some pickups. The brush and spring need to be removed to gain access to the screw. Pull the brush gently until the spring can be seen. Check the direction the spring is wound and then turn the brush to 'wind up' the spring. This reduces it's diameter allowing it to be easily removed.

If the thread is stripped, it's usually possible to tap the hole next size up and make some new over-size screws. Make a short piece of bar, drilled and tapped to suit the thread size. Then counter bore to hold a cheese head screw so that the end of the screw protrudes through the end of the bar.

Use the lathe's top slide to turn a point on the end. It may also be necessary to reduce the diameter of the screw head to allow it to fit in the recess in the cap - the same bar can be used to do this with a lock nut to hold the screw firmly.

Once the connections are made, it is always a good idea to use a multimeter to check for continuity from the plug cap through to the terminal in the distributor cap, or the brush in the pickup.

The Magneto Guys

Telephone: +44 (0)1323 840203