Dual Magnetos - Single Plugs

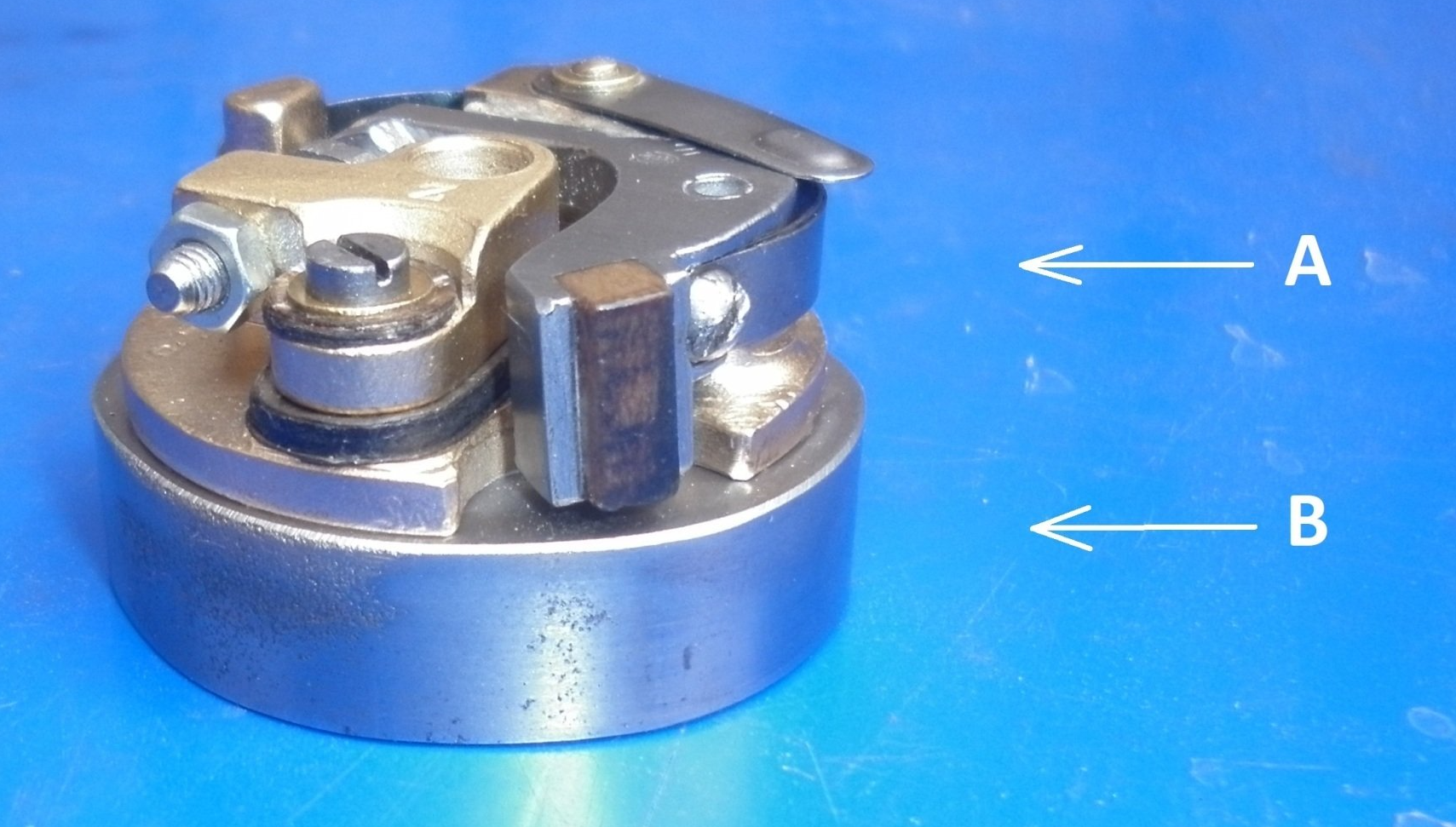

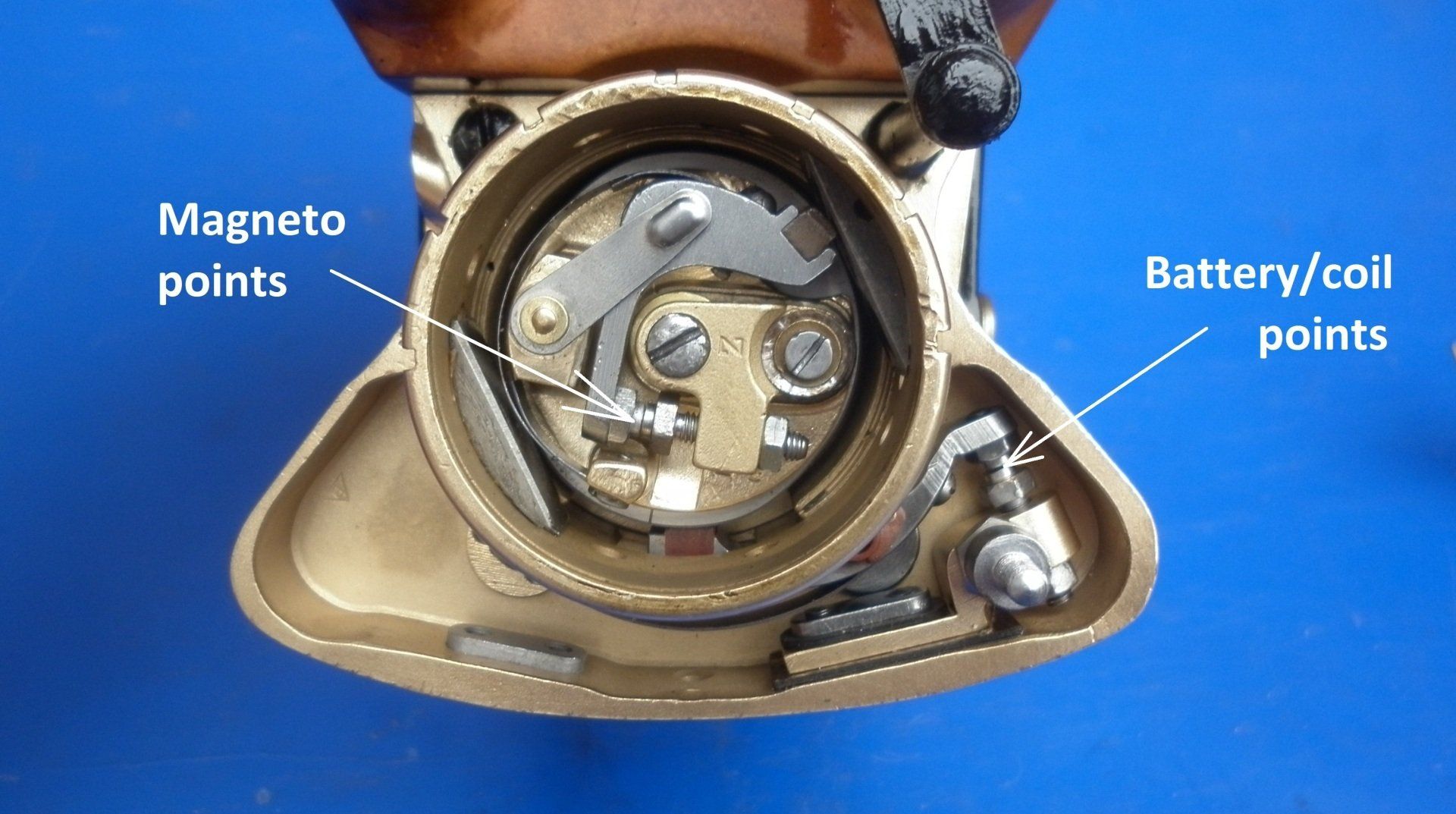

A dual magneto is basically a standard magneto system with the addition of some extra parts including a second set of contact breaker points and a cam which are used by the battery/coil section.

2: the magneto cut out is opened

3: the battery is disconnected from the HT coil to disable the battery/coil section

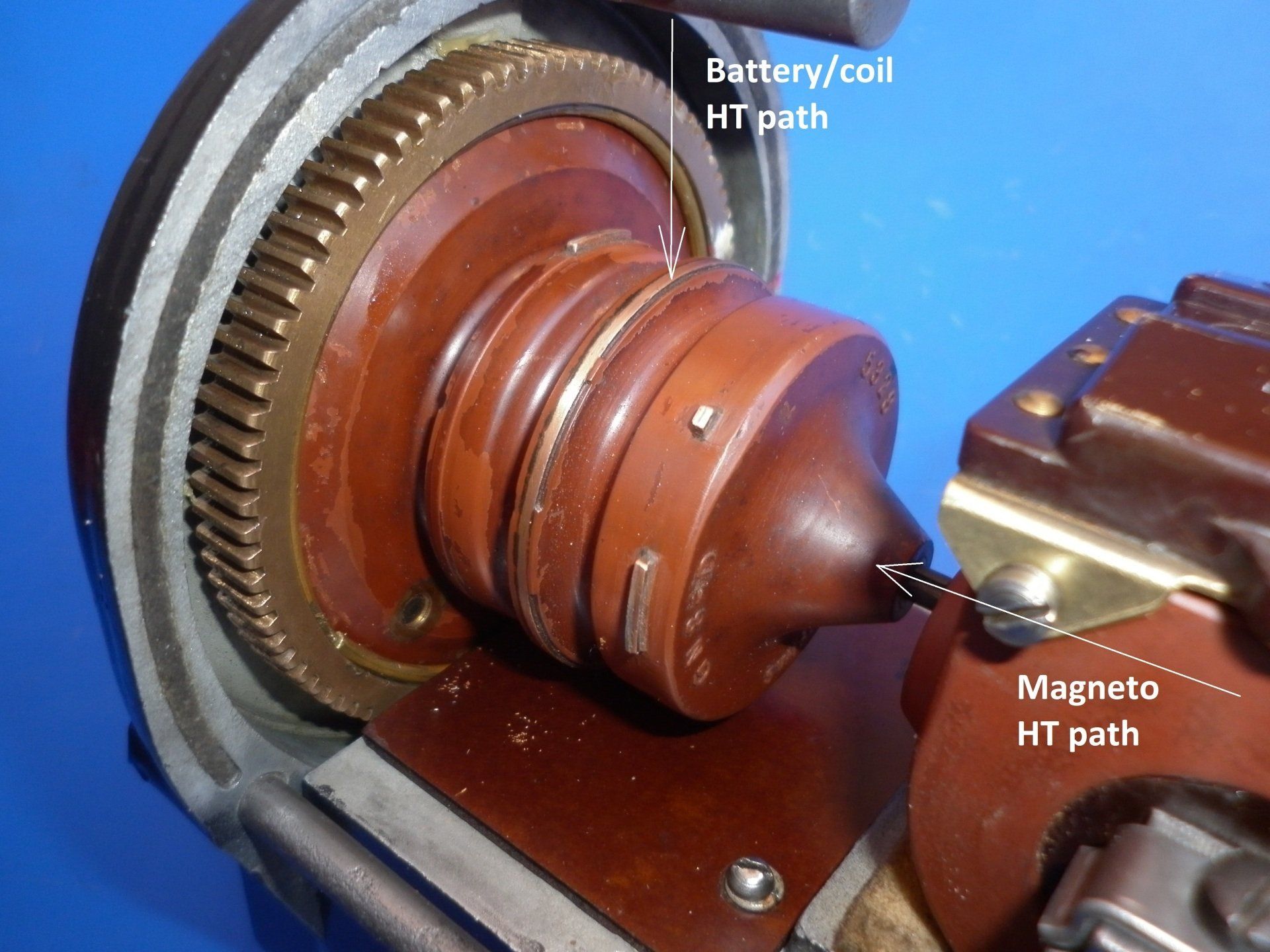

The way in which one or other of the HT sources is fed to the spark plugs is most commonly achieved by incorporating an extra terminal on the magneto's distributor cap. A carbon brush connects this terminal to the rotor arm. This picture clearly shows this terminal on a Dixie 800 magneto. Other manufacturers including Bosch, Eisemann, Simms and SEV amongst others used this method.

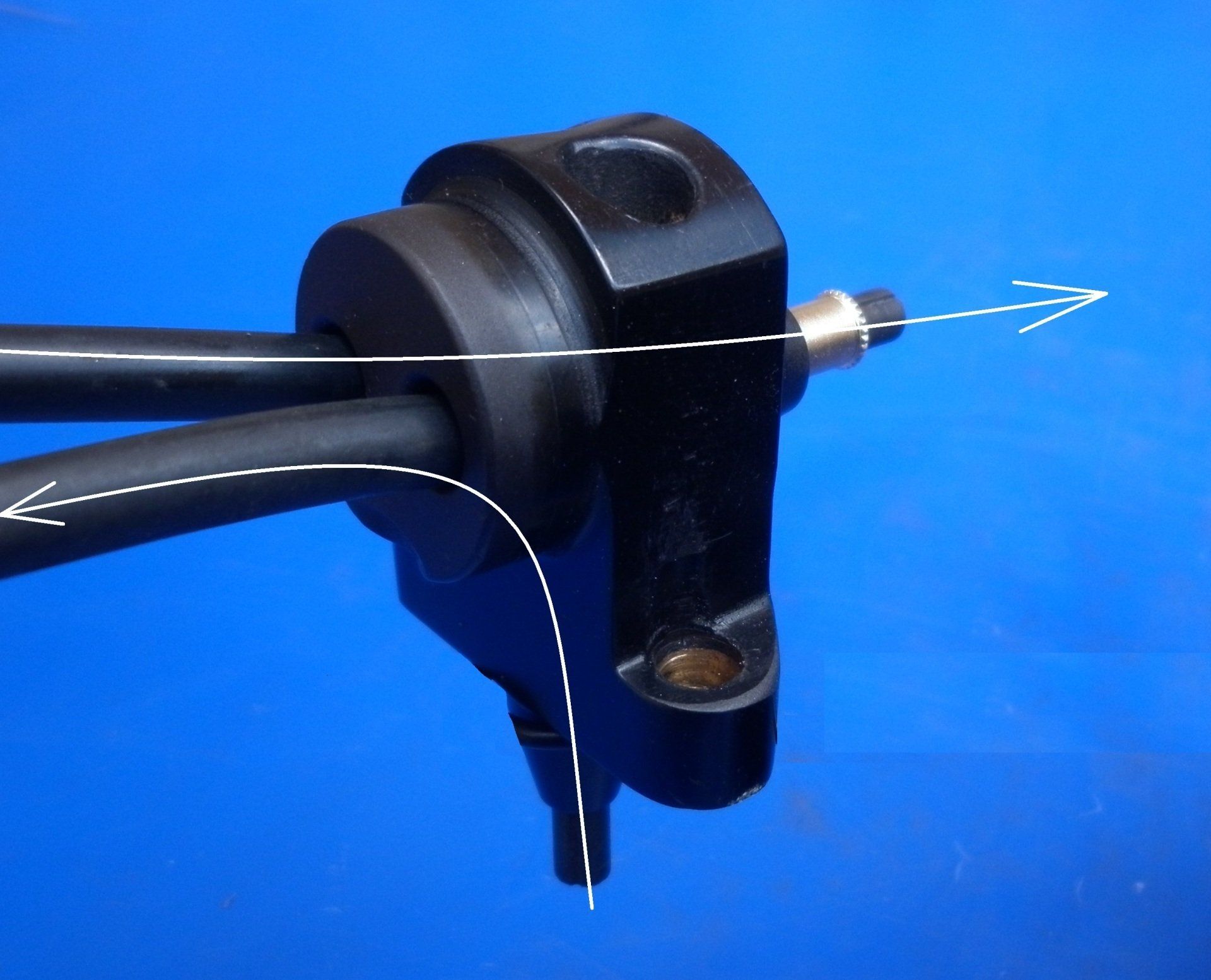

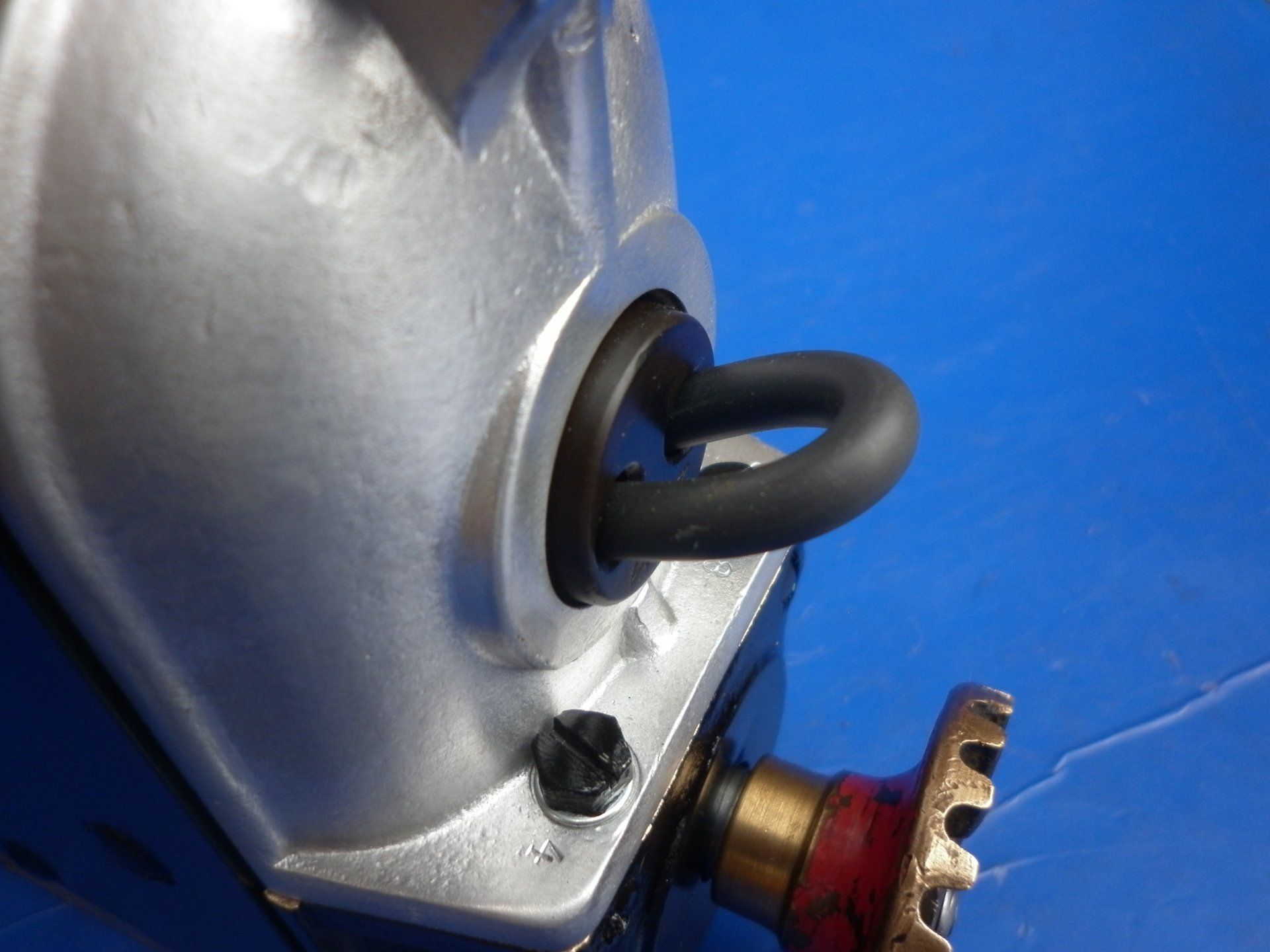

On some dual magnetos including those from BLIC and the Bosch ZR series, a special pickup is used which has two independent paths. One takes the magneto HT out of the magneto on it’s way to the changeover switch. The other path takes the selected HT from the switch into the magneto, under the arch of the magnet itself to the rotor arm and distributor and then on to the HT leads and spark plugs. This method allowed the dual magnetos to use the same rotor arm and distributor cap as the standard range of magnetos.

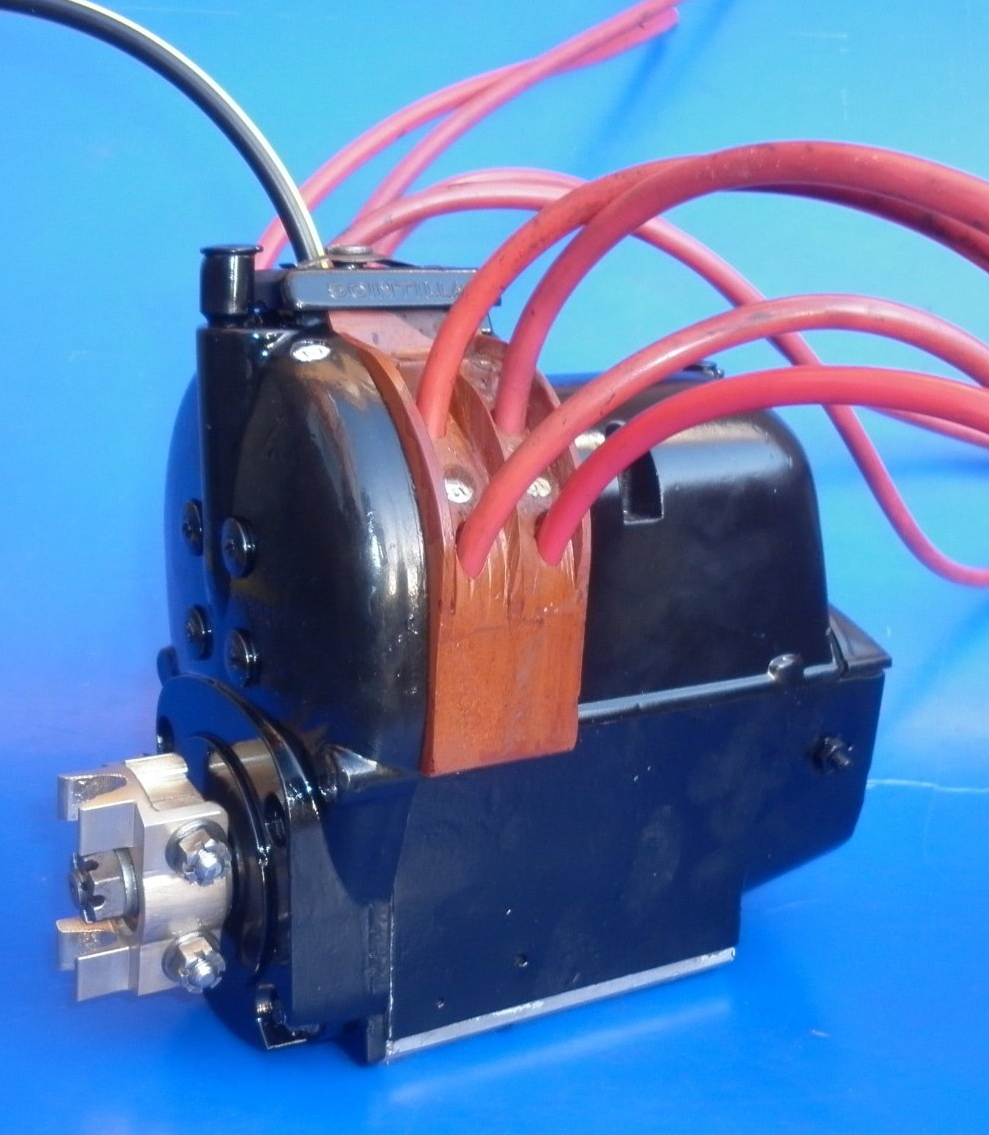

On this Scintilla GN8-D magneto, the battery/coil HT input is via the black lead into the top of the distributor cap.

It is not uncommon to find that a dual magneto is fitted on it’s own with no battery/coil system and no changeover switch. This is easily achieved by simply having a small loop of HT cable fitted between the HT output and input. The second set of points is usually left in place but is not used at all.

Magnetos used for early aircraft engines have some similarities with the dual magnetos described on this page. However, instead of using a battery/coil system as an alternative to the main magneto, they use a second independent magneto to assist starting. They are known as Aircraft Starting Magnetos .

The dual magnetos described here allow the driver to provide one set of spark plugs with HT supplied by either a magneto or battery/coil system. This is often described as a dual magneto for a single set of spark plugs (one per cylinder). Another variation is Dual Magnetos for a Twin Set of Spark Plugs (two per cylinder) .