Condensers - theory

Before considering the function of the condenser in a magneto ignition circuit, it may be worthwhile to outline the basic operation of the magneto ignition circuit as a whole.

All the time the magneto is revolving, the coil windings on the armature are passing through the magnetic field created by the permanent magnet and pole pieces – let’s call this the permanent magnetic field. While the points are closed, current flows in the primary coil which builds up another magnetic field around the winding – let’s call this one the winding magnetic field. The secondary winding is wound directly over the primary winding and so this winding magnetic field is also linked to the secondary windings. When the points open, the current flowing in the primary is interrupted and

the winding magnetic field collapses, thereby passing lines of magnetic flux through both the primary and secondary windings. This results in a high voltage – several hundred volts - to be induced in the primary winding and a considerably higher voltage – thousands of volts - to be induced in the secondary winding.

Without a condenser fitted

when the points open, the self induced voltage in the primary coil allows current to continue to flow for a time in the form of an arc between the contacts.

With a condenser fitted across the contact breaker points, when the points open the primary current flows into the condenser thereby virtually eliminating the arcing. This greatly speeds up the time taken for the primary current to drop to zero. The current flowing into the condenser will charge it up to a maximum figure after which it will start to discharge and current will flow from the condenser back into the coil. This time however, the current will be flowing in the reverse direction. This produces an even more rapid rate of change of current.

So the condenser performs two important functions:

1: Reduces the sparking which would otherwise occur at the contact breaker points every time they open. Important because this prevents the very extensive burning and pitting of the points which would rapidly wear them away.

2: Greatly increases the rate at which the primary current changes. Important because this leads to a much faster collapse of the magnetic field which in turn results in a higher voltage induced in the secondary coil leading to a much more effective spark at the spark plug.

2: Greatly increases the rate at which the primary current changes. Important because this leads to a much faster collapse of the magnetic field which in turn results in a higher voltage induced in the secondary coil leading to a much more effective spark at the spark plug.

A basic condenser consists of a sandwich of two layers of a conductor separated by a layer of an insulator, more correctly known as a dielectric in this application. The ‘capacitance’ is a function of the surface area of the conductor layers, the distance between them and the influence of a property of the dielectric layer known as permittivity - a measure of how an electric field affects, and is affected by, a dielectric.

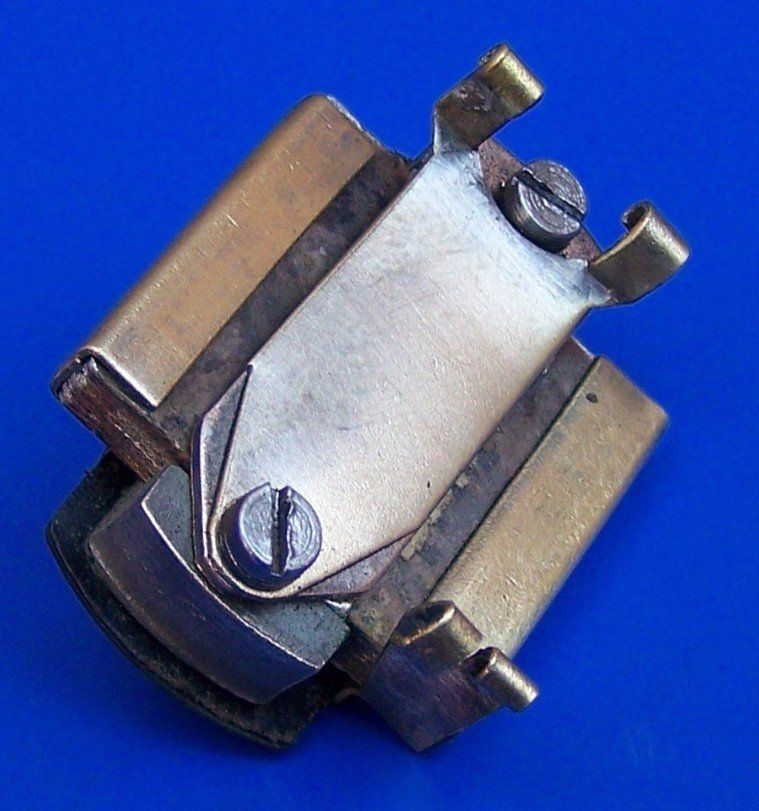

In the early days of magnetos, condensers were made of tin foil (conductor) and mica (dielectric). In order to achieve the required capacitance, the mica condensers were made up of a ‘multi layer’ sandwich to increase the net surface area of the conductor layers.

The overall shape of the condensers was not important so was usually determined by where it was located in the magneto. For a rotating coil magneto, this was usually in one end of the armature. Original condensers were often marked with the date and the initials of the inspector.

Mica condensers, although very robust and reliable were an expensive option so some manufacturers moved to a wax impregnated paper dielectric. These versions use a long, single sandwich folded to create a flat package or rolled up into a cylindrical package. Unfortunately, the life span of these capacitors is not very long as the wax tends to dry out and the insulation properties drop as a result.

Selecting a replacement condenser

Condenser is an old fashioned term really. Nowadays electrical/electronic engineers call them capacitors and they are one of the three fundamental passive electronic components along with resistors and inductors. As such, there are literally tens of thousands of different capacitors listed in the catalogues of electronic component suppliers. A few can be used as a modern day replacement for our magneto condenser – the vast majority are totally unsuitable. Although there might appear to be a lot of information given in the catalogues about the capacitors, once a capacitor is selected, it is important to look at the manufacturer’s data sheet to get the full picture.

When looking for a suitable capacitor for use in a magneto ignition system, don’t expect to see a data sheet claiming ‘suitable for use in magnetos’ - if only it were that easy! Instead, it is necessary to consider the three main properties of a capacitor which are important in this application.

1: Capacitance. The correct capacitance is important. If it is too large, then the rate of change of the primary current when the points open will be slowed down, reducing the maximum voltage produced in the secondary winding. This lower secondary voltage may then be too low to achieve a spark at the spark plug. If the capacitance is too small, then arcing will occur at the contact breaker points. Current flow across the points will carry contact material (platinum in early magnetos or tungsten in later ones) from one contact to the other. On a single cylinder magneto, primary current flow will always be in the same direction every time the points open so if the contacts show signs of pitting (a tip on one side and a corresponding pit on the other), the capacitance value needs to be adjusted. If the contact material transfers from the negative to the positive point, the condenser capacitance should be increased. If the transfer is from the positive to the negative point, condenser capacitance should be decreased. This doesn't apply to twins and other multi-cylinder magnetos because the direction of the primary current flow and therefore the points polarity alternates each time the points open. As a result, the contacts in these magnetos should remain fairly smooth with no pitting. Most condensers used in magnetos have a capacitance value between the values of 100-250nF. Note that condensers used for battery/coil ignition systems are usually twice these values because they need to cater for the, usually 12v, battery voltage already present across the points when they close. Also, it is worth mentioning that the battery/coil systems always have the primary current flowing in one direction so the notes given above re pitting and contact polarity can be used to 'fine tune' the capacitance value selected.

2: Working Voltage. This is the maximum voltage which can be safely applied to the capacitor. If voltages higher than this are applied, the dielectric will break down, normally resulting in leakage of current through the capacitor. Luckily, some capacitors with particular dielectrics and thin metal electrodes get round the problem because the metal melts or evaporates in a breakdown vicinity, isolating it from the rest of the capacitor. Voltages in the primary circuit of a magneto typically reach several hundred volts.

3: dV/dt rating. This means ‘rate of change in Voltage with respect to Time’. In simple terms this indicates how fast a capacitor can be safely charged and discharged. If the capacitor is charged and discharged at a rate faster than its dV/dt rating, it will heat up internally and quickly fail. Some capacitor data sheets do not provide a dV/dt rating. This should probably be taken as an indication that the capacitor’s performance under conditions involving rapidly changing voltages is not very good. When a dV/dt rating is given, it is usually expressed as a number of volts per microsecond. For a magneto application, we should be looking for a value of several hundred V/µs.

The capacitors used as condenser replacements by The Magneto Guys are

Evox Rifa PME271M metallized paper capacitors. These feature a high dielectric constant with excellent self-healing properties and transient handling capabilities. They are constructed of a multi-layer metallized paper dielectric encapsulated and impregnated in self-extinguishing material meeting the requirements of UL94V-O. Typical applications of the Evox Rifa PME271M capacitors are interference suppressors – class X2.

Benefits

• Rated voltage: 275 VAC (In DC Applications Recommended voltage ≤ 630 VDC)

• 100% screening factory test at 2,150 VDC *

• Excellent self-healing properties ensure long life even when subjected to frequent over voltages **

• Good resistance to ionization due to impregnated dielectric

• High dV/dt capability (600 V/μs)

• The impregnated paper ensures excellent stability and outstanding reliability properties, especially in applications with continuous operation

• Insulation Resistance Minimum Values Between Terminals C ≤ 0.33 μF ≥ 12,000 MΩ

* It is interesting to note that the data sheet states that the factory carries out a 100% screening test by applying 2,150Vdc between the terminals before carrying out all other tests. They do not recommend that this test is repeated but it does indicate that there is likely to be quite some margin over the quoted rated voltage.

** The self healing properties of Evox Rifa Impregnated Paper Capacitors is described in the data sheet as follows: If a conducting particle or a voltage surge punctures the dielectric, an arc occurs at the point of failure melting the surrounding metal and insulating the area of the breakdown. In the metallized paper capacitor as processed by Evox Rifa a breakdown caused by a short transient normally results in an improvement of the insulation resistance. Evox Rifa metallized paper capacitors are to be preferred if the capacitor is to be used where uncontrolled transient voltages can occur.

Note:

EVOX RIFA

Group was acquired by

KEMET Corporation in 2008. The PME271 range of capacitors we use can be found under either name.

Alternatives to the EVOX RIFA PME271M capacitors.

Yes, other alternatives are available which would probably/possibly work just as well. We use the EVOX RIFA capacitors because they are readily available at a reasonable cost and, more importantly, experience over many years, with them fitted in thousands of magnetos, has proven that they work well - we have had no electrical failures with them at all. We know that other magneto restorers use the EVOX RIFAs too. We also know that some magneto restorers choose to use other types. We have no experience of these other types so we stick with what we know does work. We see no need to experiment with any new options which come on the market all the time the EVOX RIFAs are available.

How we test the original capacitors and, if necessary, fit the new replacements is described on the Condensers - practical

page in the Workshop

section.