Armature Tapers - theory

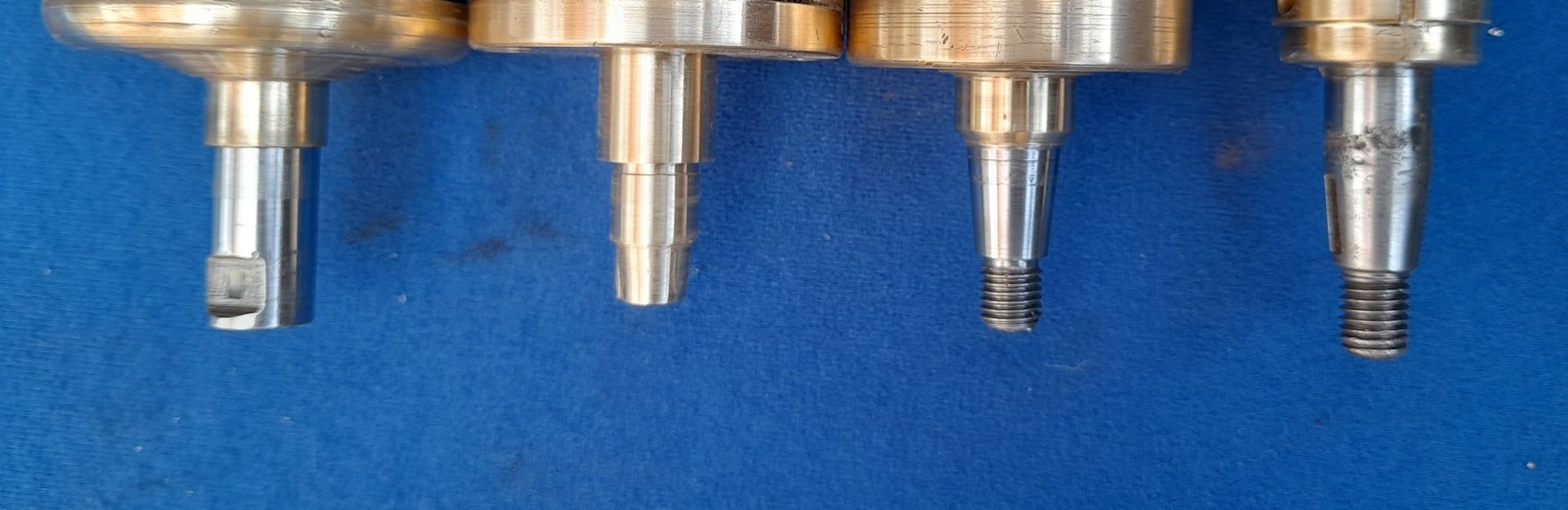

The majority of early, small magnetos used what is known as the ‘M’ taper (BTH M1, M2, for instance). Later and/or larger magnetos used the ‘K’ taper BTH KC1, Lucas K1F for instance). E and G tapers (BTH AG4, Lucas GJ4 for instance) are the largest tapers usually found and were used primarily on cars and larger vehicles. From the examples given, it can be seen that the taper letter is normally seen as part of the magneto type description, though not always. The Lucas MO1 magdyno is an obvious exception – they use the K taper! These are the most common tapers used but, as always, there are the odd exceptions to the rule! The following picture shows, from left to right, the parallel, M, K and G armature ends:

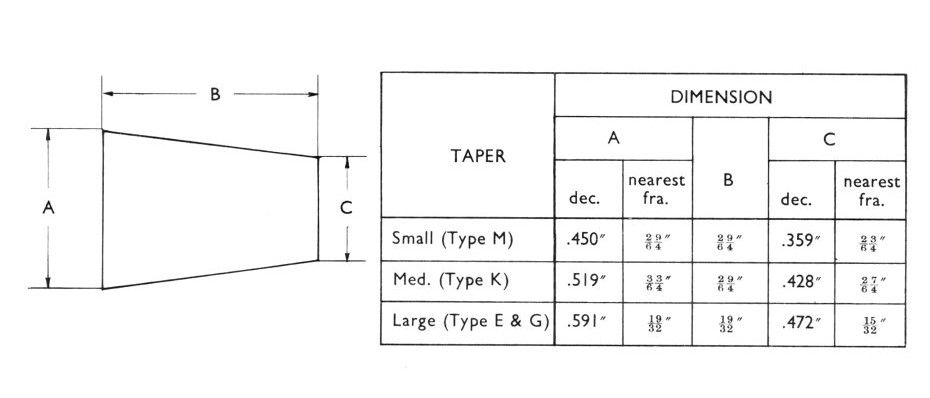

All the M, K, E and G tapers are 1 in 10 as already mentioned. The difference is in the start and finish diameters as detailed here:

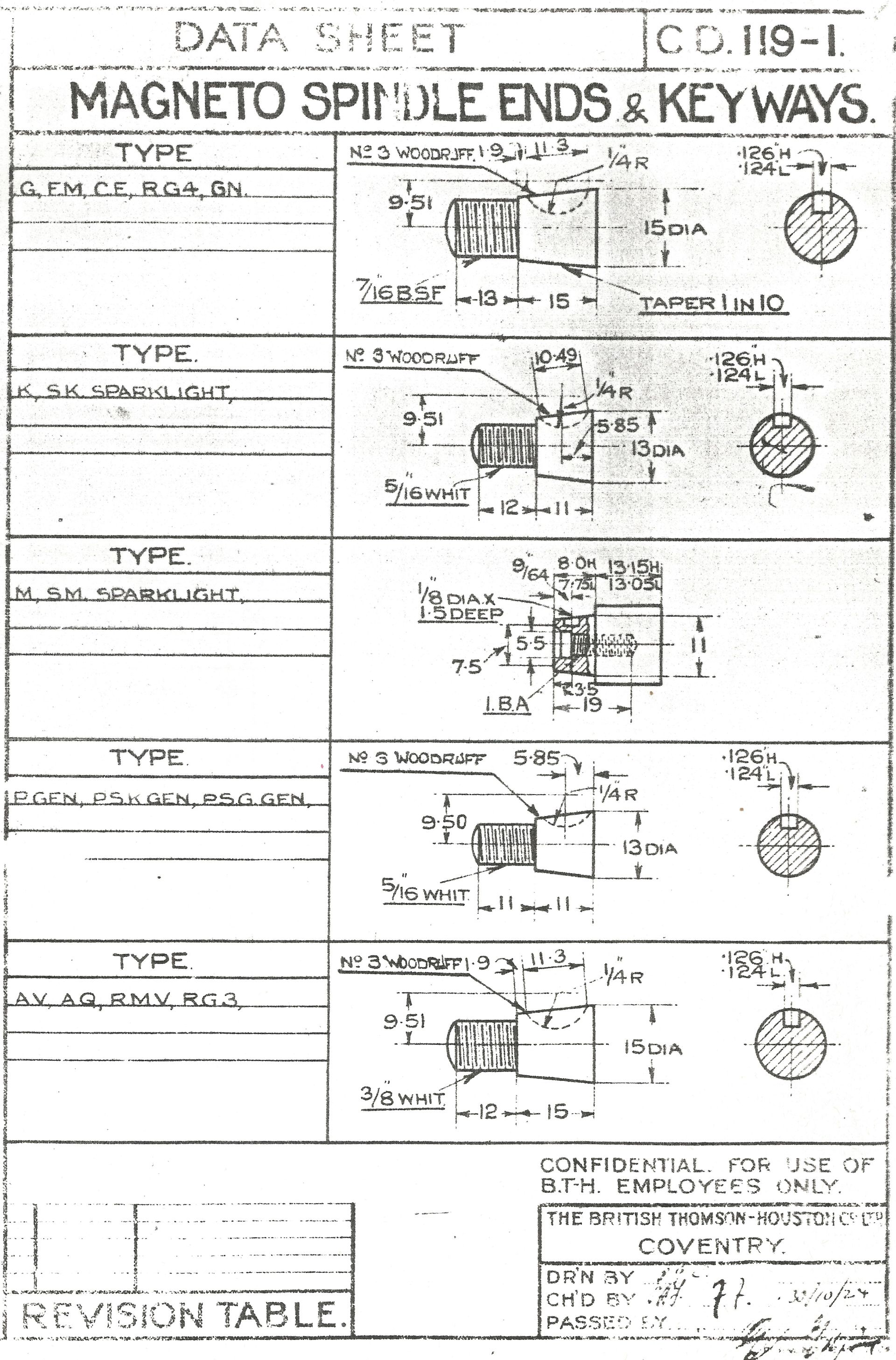

NOTE: That this BTH data sheet is dated October 1924 so is quite early. It shows the K type magnetos as using a 5/16" BSW thread. Whether this was a mistake or not is not known but In later years, the K type taper when used by BTH and many other manufacturers, was definitely 3/8" BSF!

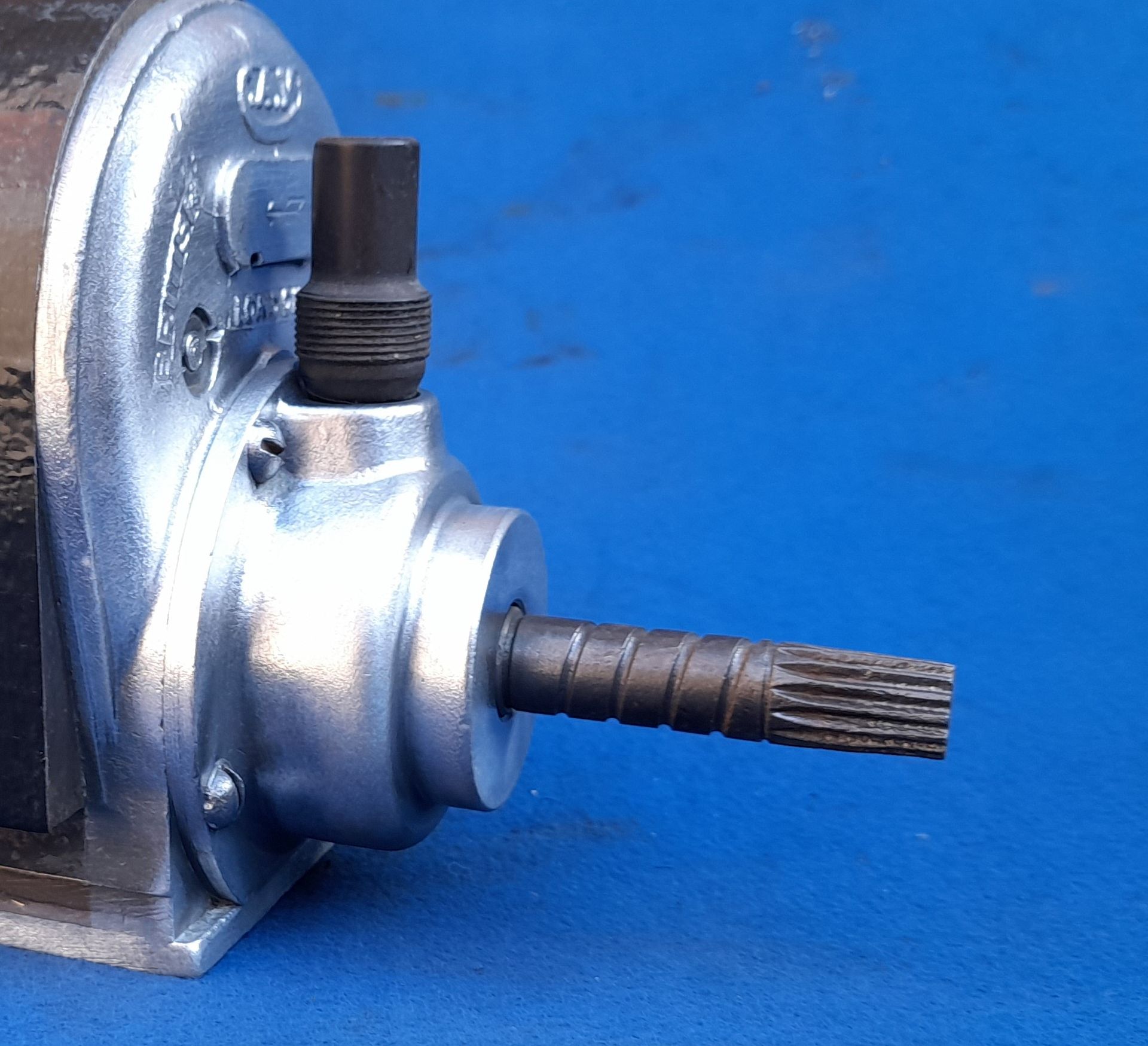

The tapers shown are the most common way of driving a magneto armature. There are always exceptions though - look at this CAV magneto!

There's an explanation of how to machine these tapers on the Armature Tapers - practical page in the Workshop section.

Incidentally, the same tapers are often found on dynamos too!